Rope Bridge project at Middle East's biggest resort

Salwa Resort, Abu Samra, Qatar

The Dahab Mountain Water and Adventure Park - Salwa Beach Resort, Doha is set to become the Middle East’s premier destination beach resort, located on three million square meters of prime coastline in the southwest corner of Qatar less than 100 kilometres from Doha. With sweeping views of the Arabian Gulf, this ambitious 362-key property will feature a wide range of remarkable facilities, including three kilometres of private beach, a luxury marina and yacht club, a themed water park, a dive centre, cinemas, a shopping mall, an Arabian village, a 2,800 square meter spa and health club, and much more. The complex is expected to open in 2019. The Hilton Salwa Beach Resort & Villas, Qatar, is expected to be the largest of its kind in the Middle East and a first for Qatar.

The Salwa Resort is designed to become one of the largest resorts and residential projects in Qatar. Constructed on 257 acres of land in the Salwa area, the beach resort and villas is a massive project that includes a water park, marina, dive centre, cinemas, pools, a health club, spa and a considerable retail space. In addition to the rooms and suites in the main hotel building, the resort will also include two small ‘villages’ of family villas.

Project requirements:

Adventure Play Area

3 Rope Bridges [each around 7m length] to be suspended at a height of around 7m between concrete and steel structures.

A 10m length Net Tunnel to be suspended 5.7m high between steel structures.

A Scramble Net ‘U’ shaped bridge at 5.6m length, at around 7m height between concrete and steel structures.

A 13.6m length safety netted walkway as part of a themed ‘Rock-Art’ concrete ‘dead-tree’.

All products to be ‘wrapped’ in safety netting.

Supply, shipping and installation.

Rope Bridge project brief - Salwa Resort, Abu Samra, Qatar

Design solutions:

3 x Rope Bridges (timber walkways), 6.2m, 6.95m and 7.56m lengths

Load points to carry Rope Bridges - M20 Swivel Load Rings [10 tonnes break-load certificated] - 6 at each end

Connection points between Load Points and Rope Bridges structural ropes - Rope 'soft-shackles' [15 T break-load certificated + preloaded labels]

Structural ropes for Rope Bridges - 12mm Manilla Superbraid Rope [9.2 T certificated break-load]

Wooden walkway - Timber Slats [Celcure treated + prepared] [45 x 220mm]

Child friendly - Anti-slip strips - 1000 x 90mm

Rope work - 12mm polyhemp rope - balustrade + frapping

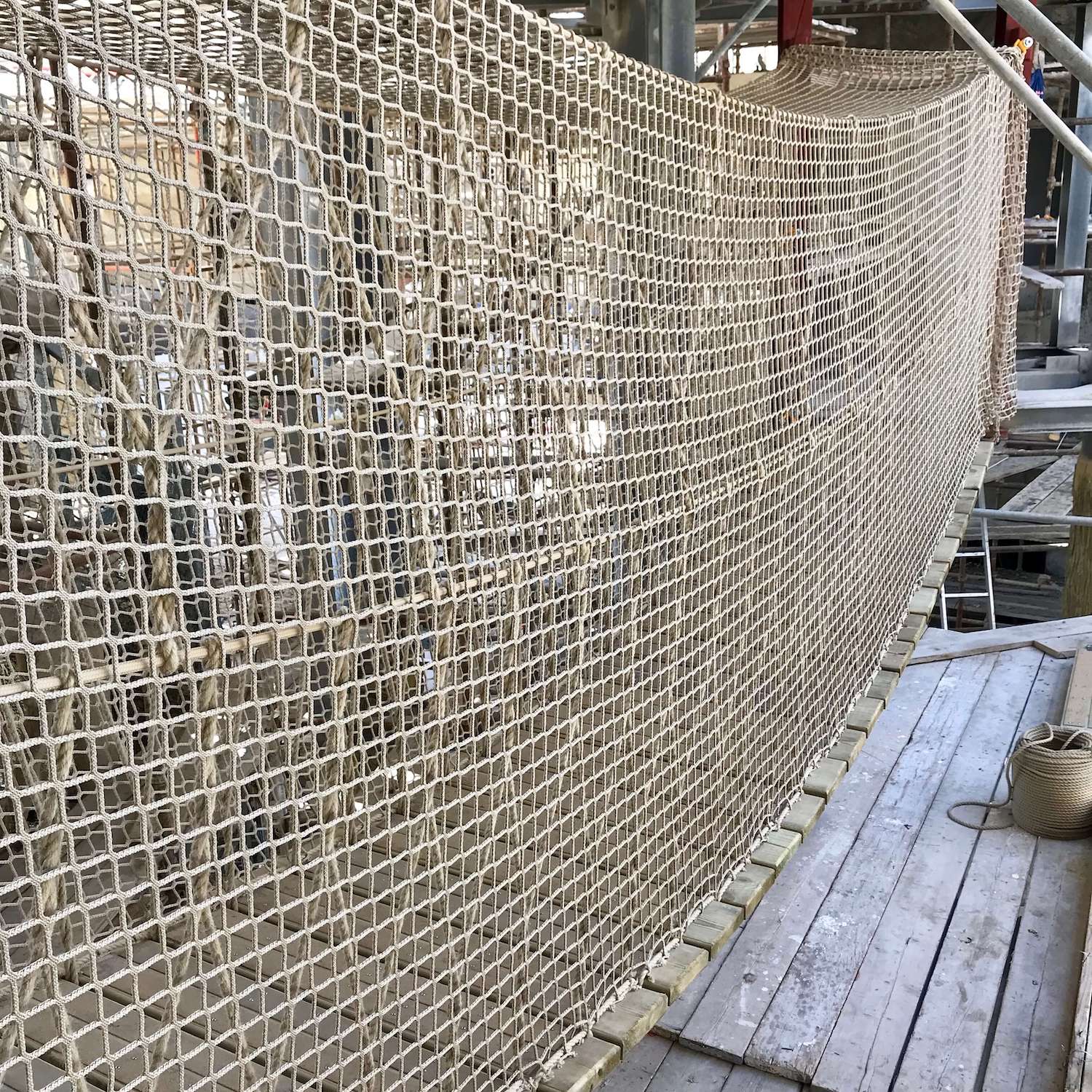

Safety - Safety netting [45mm mesh fall arrest certificated netting], both sides [to height of 1.8m + top], all in hemp colour

1 x Net Tunnel

8170mm x 1000mm log Net Tunnel, the tunnel will have 3 x 1000mm in diameter x 38 mm OD galvanised steel pipes with 4 lugs welded on equally apart. There will be 45mm x 5mm walk-on safety net attached to each steel ring [all black], the whole will further be dressed in a 45mm x 5mm walk-on safety net in hemp colour

Load points to carry Net Tunnel - G100 M20 Swivel Load Rings [10 T break-load certificated] - 4 at each end

Connection points between Load Points and Net Tunnel structural ropes - Rope 'soft-shackles' [15 T break-load certificated + preloaded labels]

Structural ropes for Net Tunnel - 12mm Manilla Superbraid Rope [9.2 T certificated break-load]

Rope work - 12mm polyhemp rope frapping

1 x Scramble Net

5600mm x 1000mm wide x 1800mm high 'U' Bridge, floor of bridge will be made from 16mm PP rope woven together with a meh size of 100mm, the sides and the roof will be made from 45mm x 5mm walk-on safety net [all black], the whole will further be dressed in a 45mm x 5mm walk-on safety net in hemp colour

Load points to carry Scramble Net - G100 M20 Swivel Load Rings [10 T break-load certificated] - 6 at each end

Connection points between Load Points and Scramble Net structural ropes - Rope 'soft-shackles' [15 T break-load certificated + preloaded labels]

Structural ropes for Scramble Net - 12mm Manilla Superbraid Rope [9.2 T certificated break-load]

Rope work - 12mm polyhemp rope frapping

1 x ‘Dead Tree’ Balustrades, 13.5m length

Load points to carry balustrades - M20 Swivel Load Rings [10 tonnes break-load certificated] - 6 at each end

Connection points between Load Points and balustrade structural ropes - Rope 'soft-shackles' [15 T break-load certificated + preloaded labels]

Structural ropes for balustrade - 12mm Manilla Superbraid Rope [9.2 T certificated break-load]

Safety - Safety netting [45mm mesh fall arrest certificated netting], both sides [to height of 1.8m + top], all in hemp colour

Installation plan:

✔️We supplied a two-man expert-installation team to work the following schedule - 14 work days, 2 travel days, 4 rest days plus 2 contingency days, plus two local staff provided by our client. Everything was prepared at our Surrey Hills workshop in the UK and shipped by 5-pallets air-freight because of the project timeline, but with a longer lead time could easily have been shipping container.

✔️We worked the math calculations for loads so that we could design and specify materials specific to the project.

Load Calculations for Salwa Resort, Abu Samra, Qatar Rope Bridge Project

✔️We designed a complete structural system based upon a load attachment swivel load ring that rotates through 360º and pivots 90º - each bridge system could work load-ring to load-ring and 6 at each end/12 in total, in the knowledge that we have a certificated and load tested unit proof tested to 2.5 times the weight load limit. We also designed and fabricated a steel bracket attachment for the load-rings that would be either welded to structural steel beams or fixed to concrete using a Hiliti® threaded rod and compound adhesive system. Hilti® were also engaged on-site to undertake ‘pull-out’ load tests on installed systems so that we had complete provenance of certification through accredited services.

✔️We researched rope systems and worked closely with Southern Ropes to design an ‘all-rope’ design with break-loads in excess of all calculations plus a safety ratio. From swivel load ring to structural rope we employed rope ‘Soft Shackles’ load-tested and certificated to 15 tonnes and Super Ropes braided in manilla colour fabric load-tested and certified to 8.4 tonnes.

Rope Bridge Soft Shackle Load Certificate

Rope Bridge SuperBraid Structural Ropes in Manilla - Certificate 1

Rope Bridge SuperBraid Structural Ropes in Manilla - Certificate 2

✔️We pre-produced deck board ‘slats’ using 1200x220x45mm, C24 and Celcure treated timbers, with rounded edges on all faces and pre-routed rope channels on the reverse. We also screw-fixed anti-slip surfaces to all deck boards.

Rope Bridge Decking Slats - Celcure Timber Treatment

Rope Bridge Decking Slats - Celcure Timber Treatment Safety Data Sheet

✔️We introduced a hemp coloured polypropylene and high tenacity safety netting with a mesh break-load at 3.2kN to the sides and above through each of the Rope Bridges and around the Scramble Net Bridge, Net Tunnel and ‘Dead Tree’ balustrades.

Rope Bridge Safety Netting Data Sheet

✔️We used 12mm polyhemp for frapping and dressing, particularly on the Rope Bridges for friction-weave and hand-weaved balustrade rope work, with a linear strength of around 1.4 tonnes and an average of 37 friction knots every 1m of Rope Bridge.